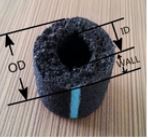

Micropore diffuser aeration hose (12-25mm)

R75.00 Excl. VAT

Micropore aeration hose, 12mm ID and 25mm OD, price per meter.

- Description

- Additional information

Description

Micropore aeration hose

We cut this hose per meter. A full roll is 100 meters.

The micropore aeration hose or pipe is made with numerous pores to create maximum fine bubbles which slowly release in the water. A pressure resistance of only 30cm (12″, 30 mbar) of H2O at normal flow rates when new. Diffuser lengths of up to 3 meters per inlet are possible at low airflow rates. At higher flow rates pressure may be 70 mbar. The micropore rubber bubble diffuser aeration hose for aquaculture is specially designed to create fine bubbles that rise slowly in the water. These fine bubbles have higher surface area which remain in the water for longer periods, enabling more efficient oxygen transfer into the water. All you need is an efficient clean air blower. Aeration Tubing has a good oxygen transfer rate and is compatible with both regenerative blowers and linear air pumps. To counteract buoyancy, hold-downs or weights are required.

Both rubber disk aeration diffusers and micropore hose diffusers are widely used in wastewater treatment for oxygen transfer. Here’s a comparison based on expected life, benefits, and common problems:

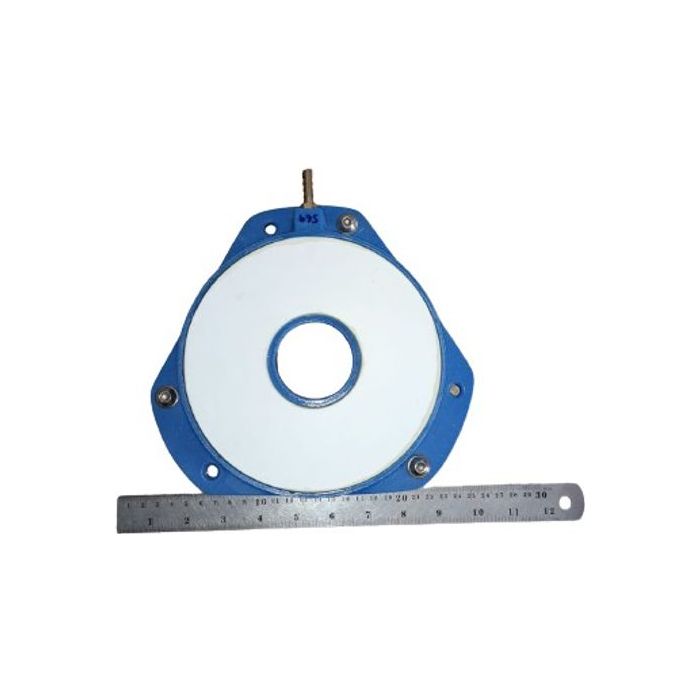

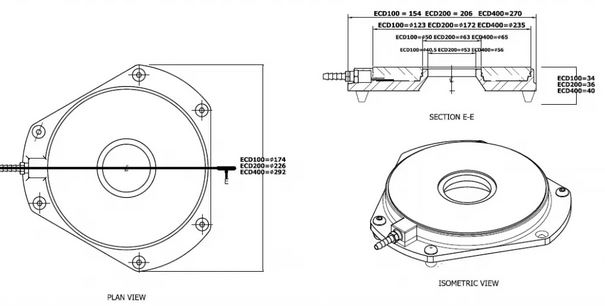

🟢 Rubber Disk Aeration Diffusers

(like the 250mm EPDM disk shown in Image 1)

✅ Benefits:

- Fine bubble diffusion: High oxygen transfer efficiency (OTE).

- Durability: EPDM or silicone membranes resist fouling and chemical attack.

- Backflow prevention: Non-return valve action when airflow stops.

- Energy efficiency: Small bubble size improves oxygen transfer, reducing power use.

- Easy maintenance: Disks can be removed and cleaned or replaced individually.

⏳ Expected Life:

- 5–8 years under normal conditions.

- Membrane degradation may begin earlier if exposed to:

- High grease or oil concentrations

- Harsh chemicals (e.g. strong oxidizers)

- Irregular cleaning/maintenance

⚠️ Common Problems:

- Clogging: Especially in systems with high solids or fats/oils.

- Backpressure: Clogged membranes can increase blower load.

- Membrane hardening or tearing over time, reducing performance.

- Scaling: In hard water areas (CaCO₃ or biological fouling).

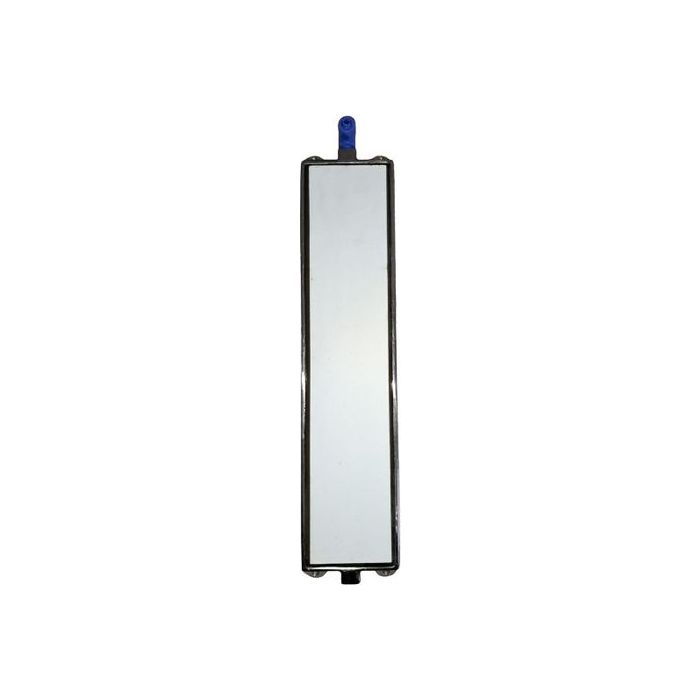

⚫ Micropore Hose Diffusers

(shown in Image 2, often made of sintered PE, rubber, or ceramic-coated rubber)

✅ Benefits:

- Flexible layout: Can cover large areas or odd-shaped tanks.

- Lower capital cost: Cheaper upfront compared to disk systems.

- Continuous bubble line: Uniform fine bubbles across the length.

- Lightweight and easy to install: Especially in retrofits.

⏳ Expected Life:

- 2–5 years, depending on material and cleaning cycles.

- Rubber-based hoses (EPDM or similar) last longer than ceramic ones.

⚠️ Common Problems:

- Fouling: Biofilm or mineral buildup inside pores.

- Bursting/Cracking: Due to overpressure or chemical degradation.

- Uneven air distribution: If hose is long or air system is unbalanced.

- Clogging over time: Leading to reduced oxygen transfer efficiency.

📊 Comparison Summary:

| Feature | Rubber Disk Diffuser | Micropore Hose Diffuser |

|---|---|---|

| Oxygen Transfer Efficiency | High (fine bubble) | Medium to High |

| Durability | 5–8 years | 2–5 years |

| Installation | Moderate | Easy |

| Maintenance | Periodic cleaning or membrane replacement | Frequent cleaning may be needed |

| Cost (Capex) | Higher | Lower |

| Layout Flexibility | Moderate | High |

| Best for | Centralized tanks, energy savings | Irregular shapes, lower-cost systems |

🧼 Maintenance Tip:

Use clean-in-place (CIP) routines with citric acid or mild chlorine solutions to extend diffuser life, especially in systems with high organic or inorganic loading.

Would you like a downloadable PDF of this comparison or assistance selecting one based on your specific application (e.g., municipal vs industrial plant, tank size, blower type)?

Additional information

| Weight | 1 kg |

|---|---|

| Dimensions | 30 × 30 × 2 cm |