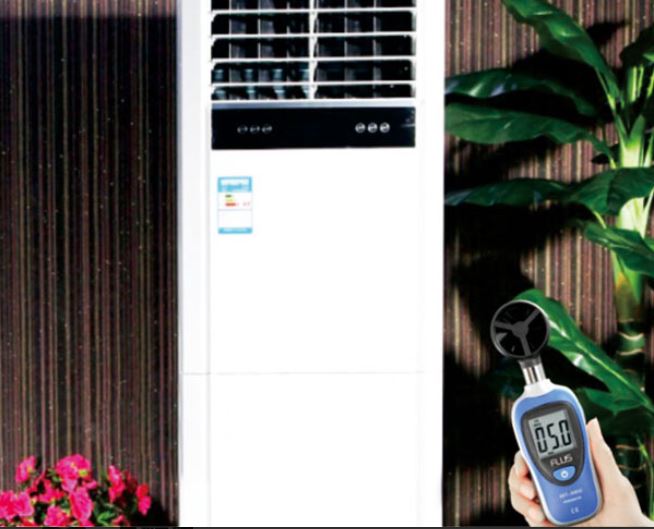

Wind Speed Tester, Thermal Anemometer GT8911

R3,975.00 Excl. VAT

Hot film anemometer. Generally in stock, else 4-6 weeks lead time.

- Description

- Additional information

- Specification

- Manual/instructions

Description

Hot film sensor (thermal) anemometer

Difference between hot wire and hot film

While both “hot film” and “hot wire” anemometers fall under the category of thermal anemometers, they are not technically the same.

Here’s a breakdown of their differences:

Hot-wire anemometers:

These use a thin wire, typically made of tungsten or platinum, that is electrically heated.

The flow of fluid over the wire cools it, and the change in the wire’s resistance is used to determine the fluid velocity.

They are known for their high frequency response, making them suitable for measuring turbulent flows.

They tend to be more fragile.

Hot-film anemometers:

These use a thin film of conductive material, such as platinum, deposited on a non-conductive substrate, like quartz.

Similar to hot-wire anemometers, the film is heated, and the change in its resistance is used to measure fluid velocity.

Hot-film sensors are generally more robust than hot-wire sensors, making them suitable for applications where the sensor might be subjected to more stress, such as in liquids or flows with particulates.

They can be manufactured in a wider variety of shapes than hot wire anemometers.

In essence:

Both rely on the principle of heat transfer to measure fluid velocity.

The key difference lies in the sensor’s construction: a wire versus a thin film on a substrate.

Therefore, while they share the same fundamental operating principle, they are distinct sensor types with different characteristics and applications.

Choose hot wire or hot film anemometer?

The choice between hot-wire and hot-film anemometers depends heavily on the specific industry and application. Here’s a breakdown of which version is generally preferred and why:

Hot-Wire Anemometers:

Preferred in:

Research and development: Especially in fluid dynamics research, aerodynamics, and turbulence studies.

Applications requiring high-frequency response: Such as analyzing turbulent flows, where rapid fluctuations in velocity need to be measured.

Clean gas flows: Where there’s minimal risk of contamination or damage to the delicate wire.

Why:

Superior frequency response: Hot-wires offer the highest frequency response, allowing for detailed analysis of turbulent flow structures.

High sensitivity: They can detect very small changes in velocity.

Hot-Film Anemometers:

Preferred in:

Applications with harsh environments: Including flows with particulates, liquids, or where mechanical stress is a concern.

Industrial settings: Where robustness and durability are essential.

Liquid flow measurements: Hot-films are better suited for liquids due to their more rugged construction.

Aerospace industry: for surface measurements, where the ability to create varied sensor shapes is very valuable.

Why:

Increased durability: The film sensor is more robust than a thin wire, making it less susceptible to damage.

Versatility: Hot-film sensors can be manufactured in various shapes, allowing for specialized measurements.

Better for contaminated flows: The film is more resiliant to damage from particles in the flow.

In summary:

If the priority is high-precision measurement of turbulent flows in clean environments, hot-wire anemometers are preferred.

If the priority is durability and the ability to withstand harsh conditions, hot-film anemometers are preferred.

Additional information

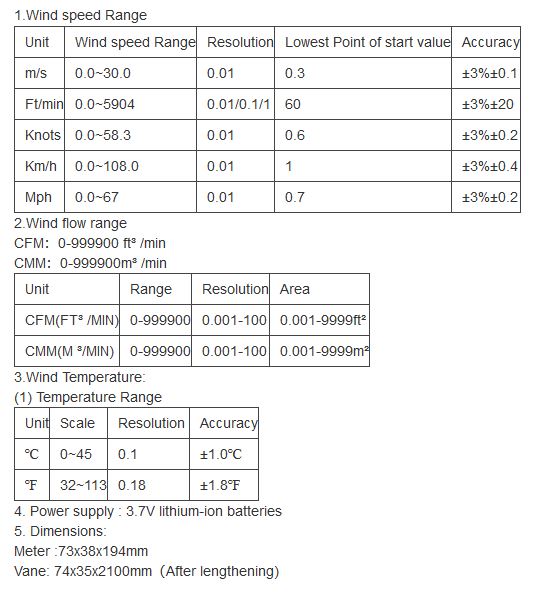

| Weight | 2 kg |

|---|---|

| Dimensions | 30 × 30 × 30 cm |

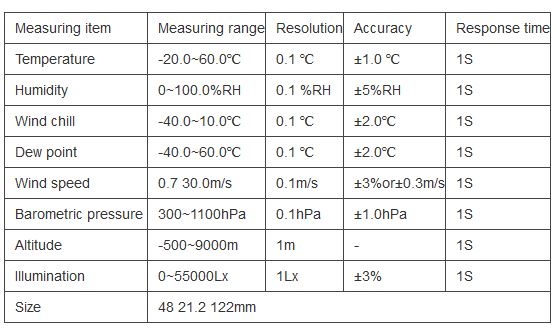

| Velocity range | 0.00 ~ 30.00 m/sec |

| Sensitivity | High sensitivity down to 0.1 m/sec |

| Units | Units of measure: m/sec, ft/min, km/h, knots, mph |

| Temperature | Air: 0 ~ 45°C |

| Memory | 960 Data points, Manual or Auto record |

| Data access | USB port for real-time connection with PC software (free download) |

| Probe length | Telescopic probe up to 1000mm with tip diameter 10mm |

| Power source | Built-in rechargeable battery (approx. 6-7 hours use) |

| Packing list | Carry case, probe, USB cable, rechargeable battery and charger |

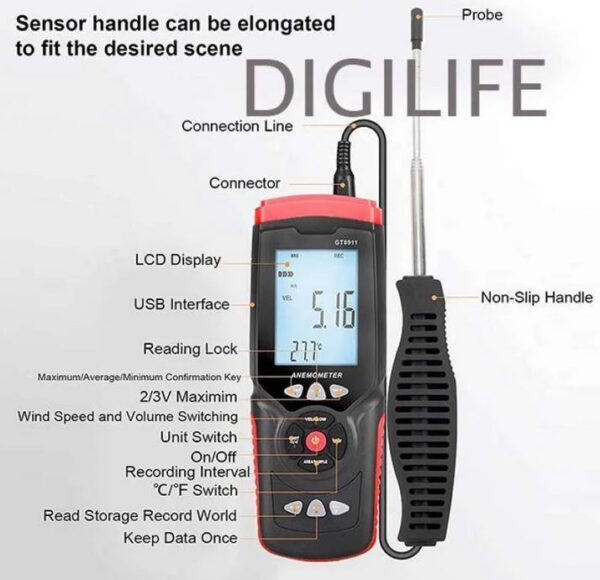

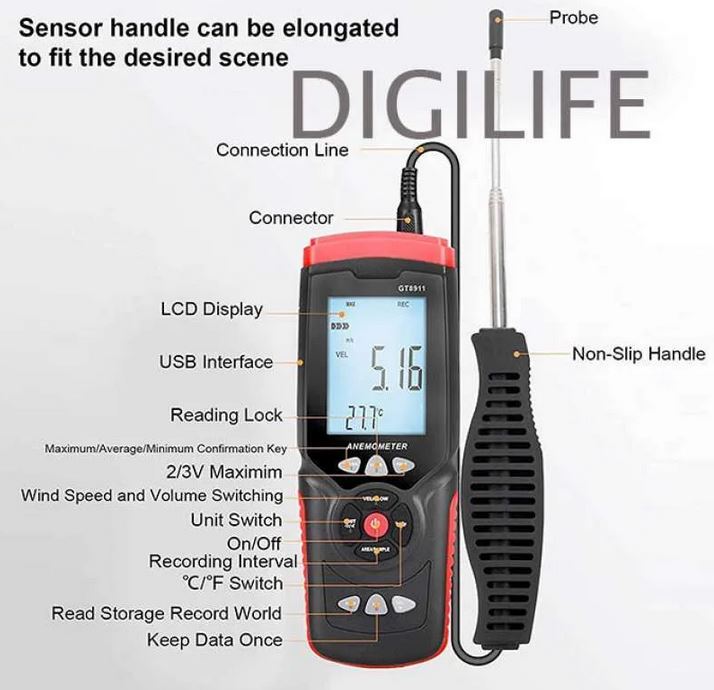

Hot film anemometer product details

- Hot film sensor more robust and not as easily damaged as hot wire

- Velocity Range: 0.00 ~ 30.00 m/sec

- High sensitivity down to 0.1 m/sec

- Units: m/sec, ft/min, km/h, knots, mph

- Air Flow calculation in m³/min or ft³/min

- Temperature – Air: 0 ~ 45°C

- Auto Zero function

- 2/3V, Max, Min, average and data hold

- Memory: 960 Data points, Manual or Auto record

- Save / Recall / Delete data on meter or transfer to PC

- USB port for real-time connection with PC software (free download)

- Telescopic probe up to 1000mm with tip diameter 10mm

- Built-in rechargeable battery (approx. 6-7 hours use)

- c/w carry case, probe, USB cable, rechargeable battery and charger