Screw air compressor 7.5Kw

R62,952.00 Excl. VAT

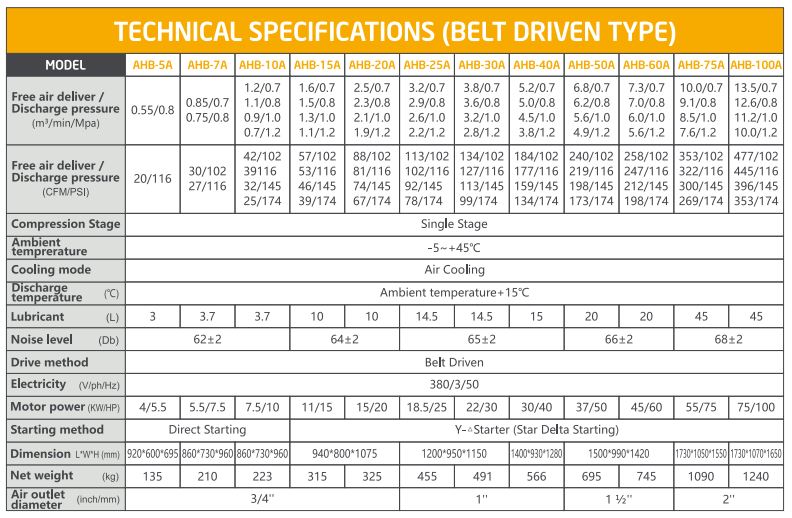

The AirHorse AHB-10A oil-filled belt-driven screw compressor (capacity 0.9 m³/min, pressure 10 bar) excels in continuous operation under the most severe operating conditions. The high performance of screw compressors of the AHB series is achieved by using high-quality construction materials, the introduction of advanced technologies, and careful control at all stages of design and manufacture.

AHB series oil-filled screw compressors are proven and reliable equipment that perform to the highest standards . 6-10 weeks lead time.

- Description

- Additional information

- Specifications

Description

AirHorse screw air compressors with V-belt drive use Germany technique which provide high quality

air low noise and high efficiency hi s more clegant easy to install simple operation and maintenance

AREAS OF USE

Car services, car washes, tire fitting;

Assembly lines (cars, household appliances);

Heavy engineering;

Extraction and processing of oil and gas;

Sandblasting works;

Packaging lines and blow molding of PET containers;

Painting works;

Chemical, energy industry;

Production of large equipment;

Construction works.

CHARACTERISTICS

High energy efficiency:

Suitable for long-term/continuous operation of the equipment ( work in 2-3 shifts, 5600-8500 hours per year );

Small size and low noise level : no separate compressor room required, can be used next to the compressed air consumer;

Ultra-low operating speed : bearings are changed less often;

Three stages of oil purification : less filter changes, better air quality at the outlet.

High efficiency:

35,000 – 40,000 hours before bearing replacement;

The total service life is 80,000 – 100,000 hours.

Belt drive:

With a belt drive, the compressor unit is connected by means of pulleys and belts to the drive motor. This design is characterized by high maintainability and ease of maintenance . And the automatic belt tensioning system reduces service costs.

Screw block GHH (Germany):

The AHB series compressors use a screw block of the German company GHH , which provides the following resource indicators:

Screw pair SKF (Sweden):

The high-precision screw pair of the Swedish company SKF ensures a long service life of the screw block.

Electric motor:

The electric motor is assembled at the facilities of the Japanese manufacturer HITACHI, has IP54 protection, high efficiency and is equipped with bearings from the Swedish concern SKF . Engine power is selected according to the volume of the propeller block, which allows maintaining sufficiently low engine speeds and increasing its service life.

The engine also has a serious power reserve, the compressor can be used for continuous operation. Withstands 20% overload.

Control Panel:

The compressor is controlled by a controller with a Russian-language interface. The status of the equipment is displayed on the LCD display .

The controller will display the following options:

Reminds you of the need for maintenance;

Turns on the energy-saving mode ( switching off the electric motor when there is no need for compressed air );

Protection and shutdown of the compressor in an emergency;

Performs a soft start

Shows operating time, saves data on operating modes ;

Prevents unauthorized modification of compressor parameters.

Suction valve HOERBIGER (Austria):

The compressor uses the suction valve of the famous Austrian company HOERBIGER , effectively regulates the supply of atmospheric air to the compression cavity.

Cooling Fan:

The top-mounted cooling fan is very efficient due to its low energy consumption and does not create additional losses during the air compression process.

The cooling system is designed for a range of ambient temperatures in the range from -5 to + 45 ° C. The temperature of the compressed air at the outlet of the compressor is only 10-15 °C higher than the ambient air temperature.

Some of the connecting lines in the compressor are designed as rigid pipe connections to minimize leakage and increase the life of the pressurized pipeline.

SIEMENS and SCHNEIDER electrical components:

The equipment uses high-quality electrical components from German manufacturers SIEMENS (Germany), SCHNEIDER (France).

MANN filters (Germany):

The compressor uses filters and filtering systems of the German company MANN . At the air inlet to the compressor, a panel filter is installed, which is designed to pre-filter the air going for compression, as well as the air cooling the compressor ( purifies up to 99.9% of the air ).

The aluminum combo cooler includes an oil cooler and a compressed air cooler and provides three-stage filtration .

The oil filter provides filtration accuracy up to 9 microns and has a resource of 20% more than analogues .

Additional information

| Weight | 220 kg |

|---|---|

| Dimensions | 100 × 100 × 100 cm |