OLH300 Advanced Colour Screen Leeb Hardness Tester

R8,000.00 Excl. VAT

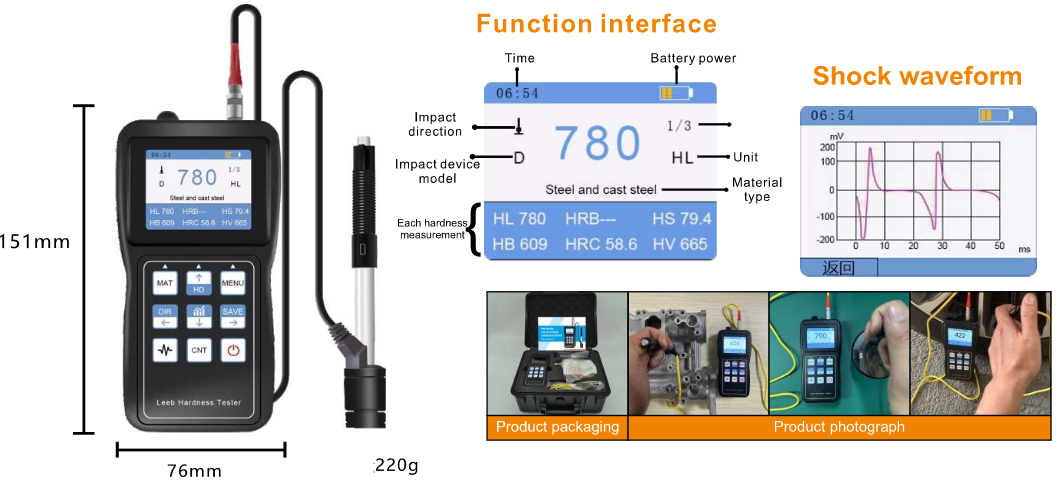

The OLH300 Advanced Colour Screen Leeb Hardness Tester is a high-performance, split-type instrument designed for fast, non-destructive hardness testing of common metals. With a vibrant full-colour LCD, multi-parameter display, and high-speed ARM Cortex-M4 processor, it provides accurate hardness readings across various scales, including HL, HB, HRC, HRB, HV, and HS. Ideal for use in labs or on-site, it supports data storage, USB connectivity, and software integration. Suitable for testing materials like steel, cast iron, aluminum, brass, and more, it comes complete with Impact Device D and all essential accessories. Lead time is 4 weeks.

- Description

- Additional information

Description

OLH300 Advanced Colour Screen Leeb Hardness Tester

This instrument is a split type measuring instrument, which can measure the hardness of common metal materials quickly, without damage and with high accuracy. It can be used in both laboratory and project site. Through the instrument measurement condition setting, it can meet the needs of a variety of measurements. It is widely used in mold, heat treatment, machining, pressure vessel, auto parts, aerospace and other industries, as well as universities, scientific research institutes, technical supervision, special inspection institutes, etc. It is a necessary instrument for nondestructive hardness testing of materials.

Portable Leeb Metal Hardness Tester for metals with multi-parameter and graphic colour LCD. Hardness testing of various metals like steel and cast steel, tool steel (CWT), stainless steel, cast iron, cast aluminium, brass, copper etc. Conversion to common hardness scales Brinell hardness (HB), Rockwell B and C hardness (HRB/HRC), Shore hardness (HS) and Vickers hardness (HV)

Equipped with upper computer software

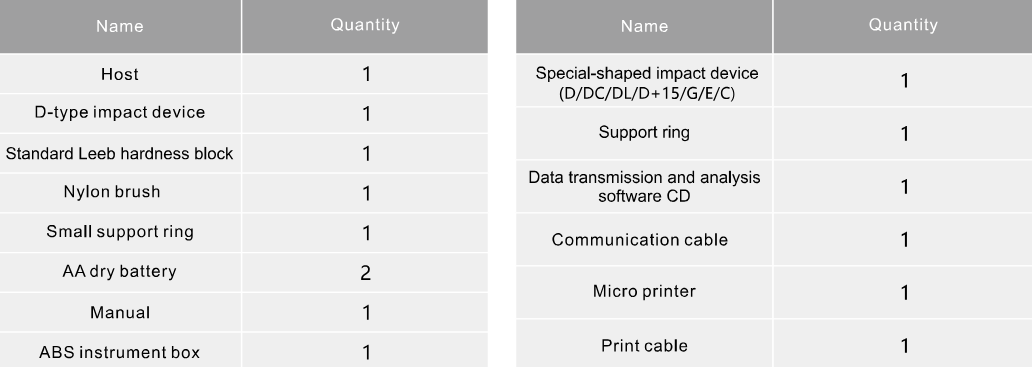

Includes

- High brightness graphic full colour LCD screen

- Multi-parameter display, bargraph and impact device waveform

- High performance fast processing using ARM processor with Cortex-M4 chip

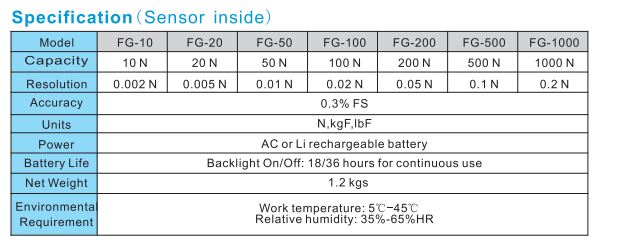

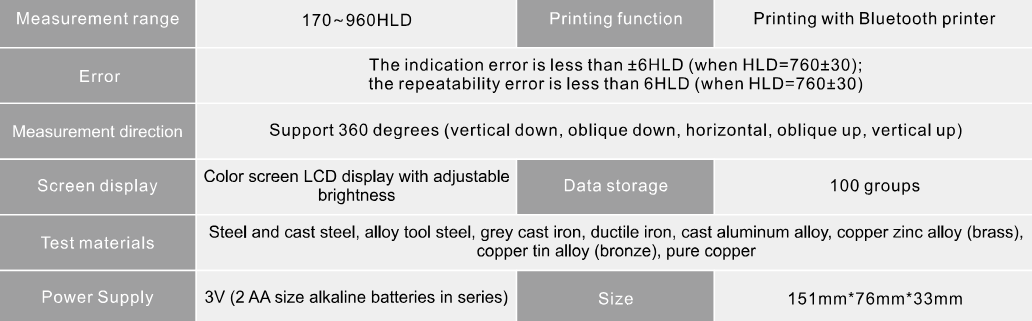

- Measuring range: 170 ~ 960 HLD (Impact device dependent)

- Accuracy: Display error ±6 HLD

- Measuring average: 1 ~ 32 times adjustable

- Conversions: HL – HRC – HRB – HB – HV – HS – Tensile Strength (UTS)

- Includes impact device D for majority of hardness testing applications

- Impact direction: Test at any angle (manual setting)

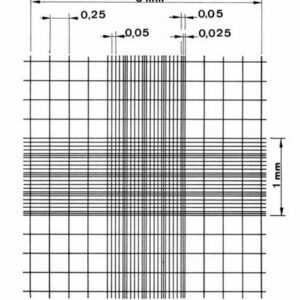

- Minimum unsupported work piece 5kg and 5mm thickness (D device)

- Materials: 10 types of common metals

- Memory: 100 groups of data (measured value, impact times, average, impact direction, material)

- Interface: USB (software included)

- User re-calibration function with test block

- c/w case, D device, cable, test block, support ring (small & large), brush, USB cable, software, batteries and manual

Features

- 1. Unique tull system display, all systems can be displayed on the main interface, no need to look up the table, no need to switch; Leeb(HL), Brinell (HB), Rockwell B (HRB), Rockwell C (HRC), Vickers (HV), Shore (HS).

- 2. It can store up to 100 groups of hardness measurement data (impact times32~1).

Each group of data includes single measurement value, average value, impact direction, times, materials, hardness system, test time and other information. - 3. It is equipped with upper computer software to facilitate reading of various data.]

- 4. A host can be equipped with a variety of different impact devices to automatically identify the type of impact device.

- 5. The high-performance ARM processor with Cortex-MO core is used as the main control chip, and the processing speed is fast.

- 6. It can be paired with a Bluetooth printer to print and archive the measurement data.

Product Technical Parameters

Standard and operational configurations

Additional information

| Weight | 1 kg |

|---|---|

| Dimensions | 40 × 40 × 40 cm |