Hardness tester Leeb140

R16,800.00 Excl. VAT

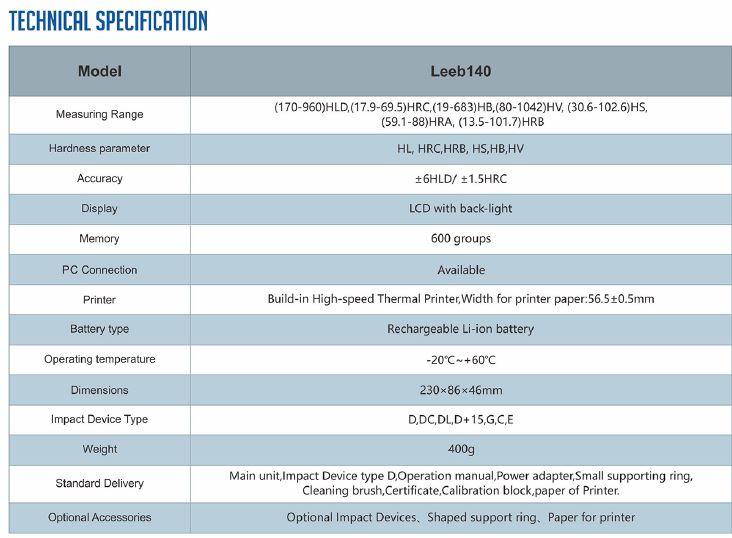

Leeb140 Portable Hardness Tester with Device Type D, built-in printer, PC software.

- Description

- Additional information

- Specifications

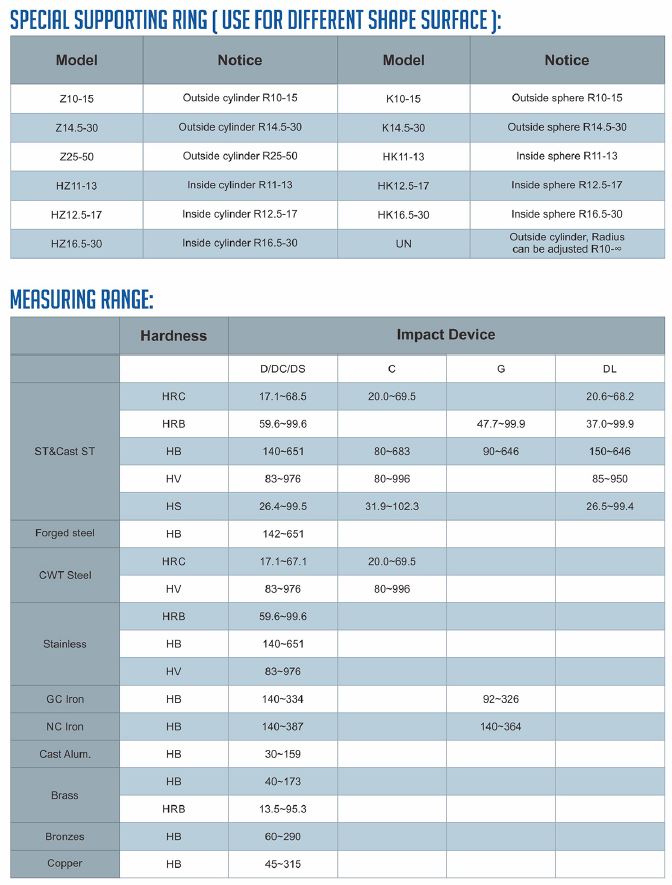

- Measuring range

Description

The Leeb140 Portable Hardness Tester with Device Type D is designed for measuring the hardness of various metal materials. Here are some of its capabilities:

- Measurement Range: It can measure hardness in different scales, including HL, HRC, HRB, HS, HB, HV.

- Accuracy: The device provides precise readings within ±0.5% (HLD=760).

- Impact Device Type D: This type is commonly used for general-purpose hardness testing and is suitable for steel, cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminum alloy, copper-zinc alloys (brass), bronze, and forged steel.

- Built-in Printer: Allows immediate printing of measurement data.

- PC Connectivity: Enables data transfer and analysis on a computer.

- Portable & Durable: Designed for field operations with a fully enclosed metal shell, making it resistant to vibration, shock, and electromagnetic interference.

FEATURES

•With built-in thermal printer

•PC Software for data transmission, analysis and measurement reports printing

•Direct calibrate on HL,HRC,HB, and freely switch to 6 different hardness scales

•Test at any angle and direction, even upside down

•Large LCD screen with back-light, showing all functions and parameters

•Conversion to tensile strength (U.T.S)

•Rechargeable Li-ion battery

APPLICATION FIELDS:

- The bearings and other parts, heavy workpieces, metal materials, pressure vessels, and failure analysis of turbine generator units and equipment.

- Mechanical or permanently assembled components have been installed, and the testing space is very limited, requiring original records of regular test results.

- Large workpieces require rapid testing and measurement across a wide range of sites

MEASURING CONDITIONS:

The weight of the measuring object must be more than 2kg.

The thickness must be more than 10mm.

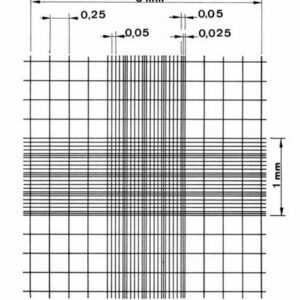

The surface roughness must be no less than 1.6 um.

Tips: If it does not meet the above conditions, the measuring object should be laminated with steel substrate by coupling agents.

MEASURING MATERIALS

Steel and cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminum alloy, copper zinc alloys (brass), an alloy of copper and tin, copper (bronze), forged steel.

Additional information

| Weight | 1 kg |

|---|---|

| Dimensions | 25 × 10 × 5 cm |